A site that meets all the essential criteria

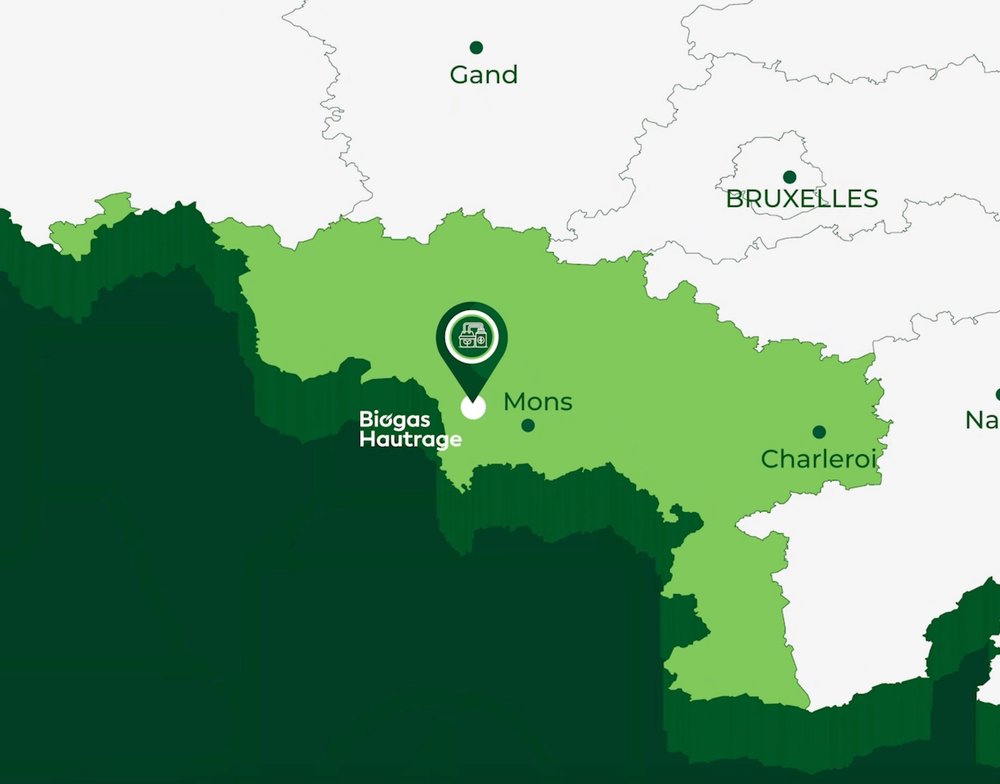

Biogas Hautrage prévoit de s’implanter sur un terrain privé situé dans l’éco-zoning de Tertre (commune de Saint-Ghislain).

- Biogas Hautrage plans to set up on private land located in the Tertre eco-zone (municipality of Saint-Ghislain).

- The site, which has been vacant for more than 20 years, offers many advantages:

- • Direct access to the canal and major roads, facilitating general logistics; • A necessary surface area of more than 7 hectares, allowing the project to be scaled in accordance with safety standards; • An industrial zone that complies with SEVESO regulations; • A direct connection to the Fluxys gas network, which is essential for biomethane injection.

Transport with limited impact

Biogas Hautrage will recover 695,000 tons of livestock manure and 205,000 tons of agro-industrial residues annually from within a 100 km radius of the site. 60% of these inputs will be transported by barge, promoting low-carbon transport and minimizing the impact on existing traffic. This corresponds to approximately one 1,775-ton barge per day.

Directly connected to major highways, the transport generated by BGH's activity represents only an increase of about 3% on current traffic, or 90 trucks per day.

A process entirely confined within closed buildings

Biogas Hautrage has been designed to operate without generating any odor or noise pollution. Inputs will be transported by covered trucks and barges. Material arriving by barge is sent through a piping system to closed storage areas without passing through the open air. Trucks are also unloaded indoors. This process prevents the spread of noise and odors.

The entire process is confined within closed buildings and coupled with a high-performance odor treatment system based on a three-stage scrubber capable of eliminating up to 95% of odorous compounds (ammonia, hydrogen sulfide, etc.), with temperature-independent operation and automated treatment based on odor load. The whole system is backed up by an emergency generator. The redundancy of the odor treatment lines coupled with the emergency generators ensures maximum reliability.

Finally, the project is designed to strictly comply with regulatory thresholds for noise and odor, thanks to equipment sized to ensure the comfort of local residents and respect for the environment at all times.

A low-threshold Seveso classified activity

Due to the nature of its activity, Biogas Hautrage will be classified as a low-threshold Seveso site. This classification implies a significant number of standards and safety rules to be complied with. BGH will implement and comply with these obligations, in particular through the sizing of its unit, but also through regular inspections by independent bodies and authorities, staff training, clear signage on site, the implementation of an internal emergency plan approved by the responsible authorities, the training of a first response team, etc.

Comprehensive treatment of liquid digestate

Thanks to a complete digestate treatment line, Biogas Hautrage will produce concentrated organic fertilizers, making it independent of spreading windows and variations in demand for liquid digestate. The project is based on a circular approach: returning to Walloon soil the nutrients from the materials provided by partner farmers.

In concrete terms, the unit will be equipped with a comprehensive liquid digestate treatment system. This will generate concentrated organic fertilizers and water which, after treatment, can be discharged into the canal in accordance with current standards.

Any questions?

Whether you are a local resident, a farmer interested in collaboration, or simply curious, our team is here to help.